Westinghouse Portable Generator WGen7500 User Manual

Content

Introduction

The Westinghouse Portable Generator WGen7500 is a powerful and reliable solution for backup power needs, delivering 7,500 running watts and 9,500 peak watts. Designed for convenience, it features a push-button start and remote start capability, making it easy to operate. With a robust 420cc engine, this generator can run for up to 16 hours on a single tank of gasoline. Manufactured by Westinghouse, it is priced at approximately $899.00, making it an excellent choice for home backup or outdoor activities.

COMPONENTS

CONTROL PANEL COMPONENTS

- Push-Button START/STOP: Push once to automatically start the engine. Push again to stop the engine.

- Battery Switch: Turns battery ON and OFF. Must be ON before electric or remote start.

- Data Center: Toggle to show voltage, frequency, total hour meter, and run/maintenance timer.

- Main Circuit Breaker: The main circuit breaker controls total output of all outlets to protect the generator from overload or short circuit.

- 120/240 Volt AC, 30 Amp NEMA 14-30R Twist-Lock Receptacle: Receptacle can supply a maximum of 30 Amps.

- 120 Volt AC, 20 Amp Duplex GFCI NEMA 5-20R Receptacles: Receptacles can supply a maximum of 20 Amps.

- 20 Amp AC Circuit Breakers: Circuit breakers limits the current that can be delivered through the NEMA 5-20R receptacles to 20 Amps.

- Ground Terminal: The ground terminal is used to externally ground the generator.

- Smart Switch Outlet: Connects the Westinghouse ST Switch (sold separately) to the control panel.

- Battery Charging Port: Used to charge the battery with the included battery charger.

- Battery Indicator: Indicates that power is ON. Light will remain illuminated while the unit is ON.

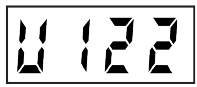

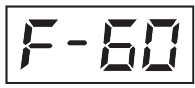

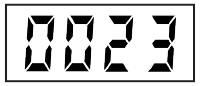

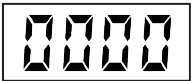

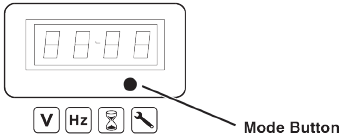

DATA CENTER

|  |  |  |

| Voltage: Displays current voltage output. | Frequency (Hz): Displays power output frequency in Hertz. | Lifetime Hours: Displays the lifetime run hours. | Run Time/Maintenance: Displays current run time. Resets to zero when shut down. Maintenance reminder displayed when required. |

Push the Mode button to cycle through the data display modes.

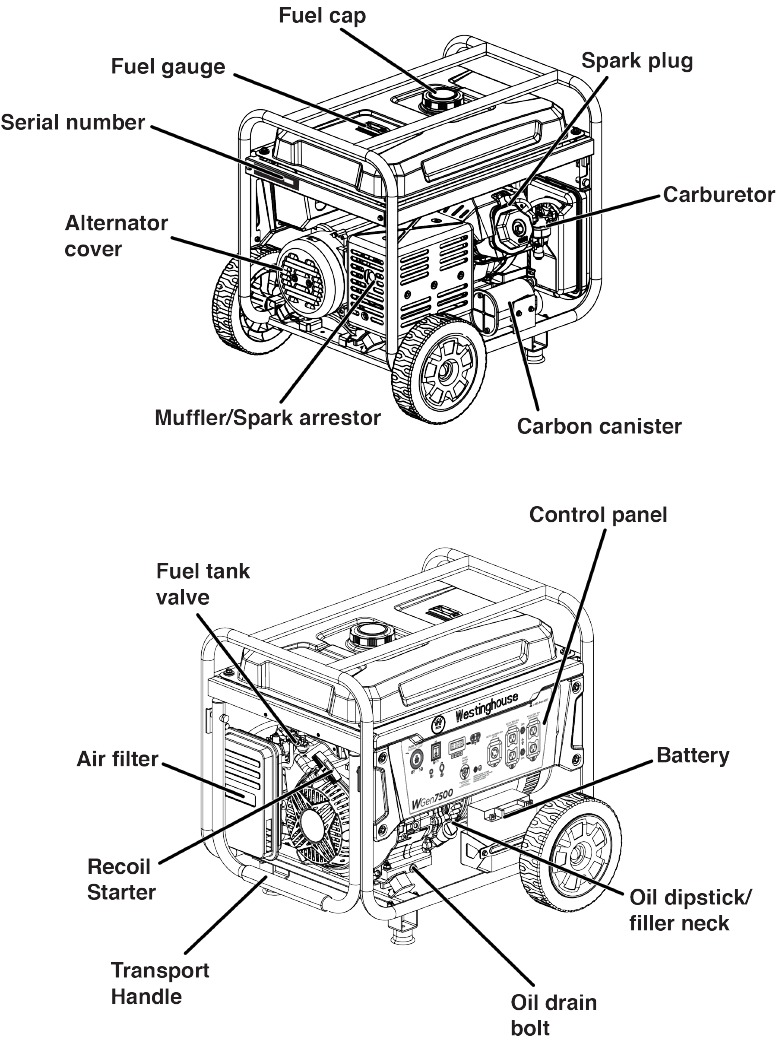

GENERATOR COMPONENTS

Specifications

The Westinghouse WGen7500 boasts several key features that make it a standout in its category:

- 420cc 4-Stroke OHV Engine

- 9,500 Peak Watts / 7,500 Running Watts

- 6.6-Gallon Fuel Tank with 11-Hour Run Time at 25% Load

- Two GFCI 120V 5-20R Outlets and One 120/240V 30A L14-30R Outlet

- Remote Start Key Fob and Electric Start

- Transfer Switch Ready L14-30R 30A Outlet

- VFT Data Center Display with Real-Time Fuel Level, Voltage, and Runtime

- Heavy-Duty Steel Frame with Lift Brackets for Easy Handling

- Compliant with EPA and CARB Standards

Description

The Westinghouse WGen7500 is engineered to provide reliable power in various settings. Its powerful 420cc engine ensures that you get the necessary wattage to run everything from home appliances during a power outage to heavy-duty tools on a job site. The generator's design includes a durable steel frame and lift brackets, making it easy to transport and set up. The VFT data center display provides real-time information on fuel level, voltage, and runtime, helping you manage your power needs efficiently.

The inclusion of multiple outlets and a transfer switch-ready design allows for seamless integration into your electrical system. The remote start feature adds convenience, allowing you to start the generator from a distance. With its EPA and CARB compliance, you can use this generator with confidence in any region.

ASSEMBLY

CARTON CONTENTS

CAUTION

Weight hazard. ALWAYS have assistance when lifting the generator.

- Carefully open the carton.

- Remove and save the carton contents.

- Remove and discard the packing tray.

- Unfold the top of the plastic bag enclosing the generator.

- Carefully cut the vertical corners of the carton to access the generator.

- Recycle or dispose of the packaging materials properly.

CARTON CONTENTS

- User manual

- Quick Start Guide

- Remote start key fob (attached to recoil starter)

- 1.16 Quart (1.1 Liter) bottle of SAE 10W-30 Oil

- Battery charger

- Spark plug socket wrench

- Oil Funnel

- Assembly wrench

Wheel and mounting foot components

- Mounting foot (2)

- Flange bolt, M8 (4)

- Wheel (2)

- Axle pin (2)

- Washer (2)

- Cotter pin (2)

If any parts are missing, contact our service team at [email protected] or call 1-855-944-3571.

INSTALL FEET AND WHEELS

NOTICE

Assembling the generator will require lifting the unit on one side. Install the mounting feet and wheel before adding fuel or oil.

- Place generator on a flat surface.

- Tip the generator on a piece of cardboard or other soft material to protect the frame paint and prevent the generator from sliding.

With the included wrench, install the mounting feet to the frame as shown.

Install the wheels as shown.

Note: The wheels are only intended for hand transport. The wheels are not suitable for towing the generator either on or off-road.

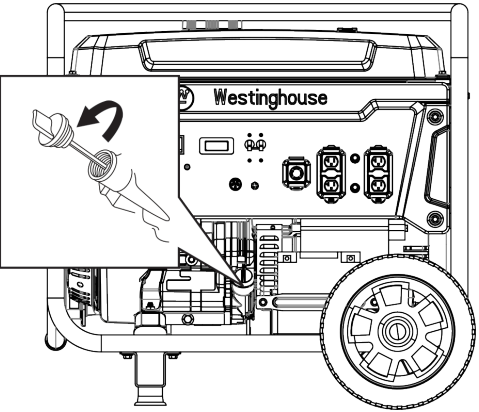

INITIAL OIL FILL

NOTICE

THIS GENERATOR HAS BEEN SHIPPED WITHOUT OIL. DO NOT attempt to crank or start engine before it has been properly serviced with recommended oil. Failure to add engine oil before starting will result in serious engine damage.

NOTICE

Use of 2-stroke/cycle oil or other unapproved oil types can cause severe engine damage that is not covered under warranty.

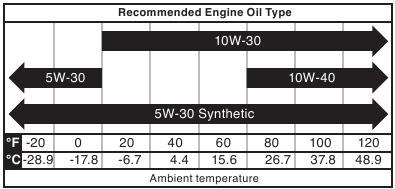

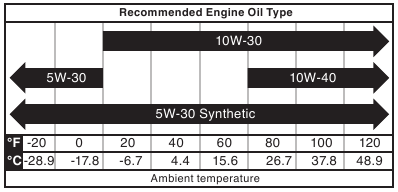

The included, recommended oil type for typical use is 10W-30 engine oil. If running the generator in extreme temperatures, refer to the following chart.

On a level surface, remove the oil dipstick

- Using the supplied funnel and oil, add oil into oil filler neck.

Note: As residual oil from the factory may remain in the engine, add the oil incrementally near the end of the bottle to prevent overfilling the engine. See Engine Oil Level Check in the Maintenance section. - Replace the oil dipstick and hand-tighten.

FUEL

WARNING

Fire and explosion hazard. NEVER use a gasoline container, gasoline tank, propane connector hose, propane tanks, or any other fuel item that is broken, cut, torn or damaged.

DANGER

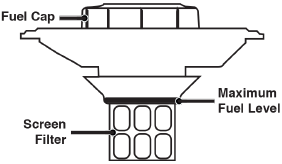

Fire and explosion hazard. DO NOT overfill fuel tank. Fill only to the red fill ring located in the in-tank fuel screen filter. Overfilling may cause fuel to spill onto engine causing a fire or explosion hazard.

DANGER

Fire and explosion hazard. NEVER refuel the generator while the engine is running. ALWAYS turn the engine off and allow the generator to cool for two minutes before refueling.

NOTICE

DO NOT use E15 or E85 fuel in this product. Engine or equipment damage caused by stale fuel or the use of unapproved fuels (such as E15 or E85 ethanol blends) is not covered by warranty. Only use unleaded gasoline containing up to 10% ethanol.

FUEL REQUIREMENTS

- CLEAN, FRESH, unleaded gasoline, 87–93 octane.

- Up to 10% ethanol (gasohol) is acceptable (where available; non-ethanol fuel is recommended).

- DO NOT use E85 or E15.

- DO NOT use a gas oil mix.

- DO NOT modify the engine to run on alternate fuels.

- DO NOT fuel indoors.

- DO NOT create a spark or flame while fueling.

USING FUEL STABILIZER

Adding a fuel stabilizer (not included) extends the usable life of fuel and helps prevent deposits from forming that can clog the fuel system. Follow the manufacturer's instructions for use.

ALWAYS mix the correct amount of fuel stabilizer to gasoline in an approved gasoline container before fueling the generator. Run the generator for five minutes to allow the stabilizer to treat the entire fuel system.

FILLING THE FUEL TANK

- Turn the generator OFF and allow to cool for a minimum of two minutes before fueling.

- Place the generator on level ground in a well ventilated area.

- Clean area around fuel cap and remove the cap slowly.

NOTICE

Only fill the tank from an approved gasoline container. Make sure the gasoline container is internally clean and in good condition to prevent fuel system contamination.

Slowly add the recommended fuel. DO NOT overfill. Fill only to the red maximum fill ring on the fuel screen filter visible in the filler neck.

- Install the fuel cap.

NOTICE

Fuel can damage paint and plastic. Use caution when filling the fuel tank. Damage caused by spilled fuel is not covered under warranty.

NOTICE

Clean the fuel screen filter of debris before and after each fueling. Remove the fuel screen filter by slightly compressing it while removing it from the fuel tank.

CONNECT THE BATTERY

A quick-connect battery plug is pre-installed on the battery. Remove the cable tie securing the plugs then push firmly to connect them.

Note: The generator is equipped with a battery charging feature. Once the engine is running, a small charge will slowly recharge the battery.

OPERATION

GENERATOR LOCATION

Read and understand all safety information before starting the generator.

Danger

Using a generator indoors CAN KILL YOU IN MINUTES. Generator exhaust contains carbon monoxide. This is a poison you cannot see or smell.

NEVER use inside a home or garage, EVEN IF doors and windows are open.

Only use OUTSIDE and far away from windows, doors, and vents.

NEVER operate the generator inside any building, including garages, basements, crawlspaces, sheds, enclosure, or compartment, including the generator compartment of a recreational vehicle.

Electric Danger

Electrocution hazard. NEVER use the generator in a location that is wet or damp. NEVER expose the generator to rain, snow, water spray, or standing water while in use. Protect the generator from all hazardous weather conditions. Moisture or ice can cause a short circuit or other malfunction in the electrical circuit. Using a generator or electrical appliance in wet conditions, such as rain or snow, or near a pool or sprinkler system, or when your hands are wet, could result in electrocution

WARNING

Fire hazard. Only operate the generator on a solid, level surface. Operating the generator on a surface with loose material such as sand or grass clippings can cause debris to be ingested by the generator that could block cooling vents or the air intake system.Allow the generator to cool for 30 minutes before transport or storage.

The generator should be on a flat, level surface at all times (Even while not in operation). The generator must have at least 5 ft. (1.5 m) of clearance from all combustible material.

DO NOT operate the generator in the back of a SUV, camper, trailer, truck bed (regular, flat, or otherwise), under stairs, next to walls or buildings, or in any other location that will not allow for adequate cooling of the generator and/or the muffler. DO NOT contain generators during operation.

DANGER

Asphyxiation hazard. Place the generator in a wellventilated area. DO NOT place the generator near vents or intakes where exhaust fumes could be drawn into occupied or confined spaces. Carefully consider wind and air currents when positioning the generator.

GROUNDING

WARNING

Shock hazard. Failure to properly ground the generator can result in electric shock.

NOTICE

Only use grounded 3-prong extension cords, tools, and appliances, or double-insulated tools and appliances.

The generator neutral is bonded to the frame. There is a permanent conductor between the generator (stator wire) and the frame. If this generator will be used only with cord and plug equipment connected to the receptacles mounted on the generator, National Electric Code does not require that the unit be grounded. However, other methods of using the generator may require grounding to reduce the risk of shock or electrocution.

Before using the ground terminal, consult a qualified electrician, electrical inspector, or local agency having jurisdiction for local codes or ordinances that apply to the intended use of the generator.

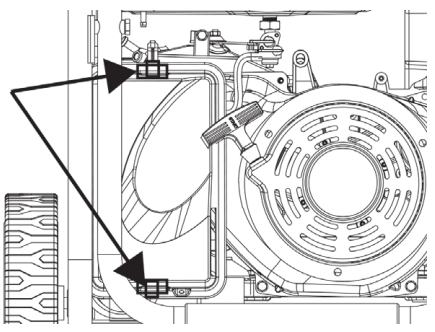

DISCONNECTING THE BONDED NEUTRAL

Removing the bonded neutral disables the GFCI protection from the 5-20R receptacles. The bonded neutral should only be removed under specific circumstances. Consult a qualified electrician to determine if your situation requires disconnecting the bonded neutral.

- Remove the alternator cover.

Remove the bonded jumper wire and reinstall the nut.

Remove the nut securing the neutral ground wire and attach the bonded jumper wire. Reinstall the nut.

- Reinstall the alternator cover.

Important Information

Apply a new "NEUTRAL UNBONDED" Label over the "NEUTRAL BONDED TO FRAME" label on the front of the control panel.

HIGH ALTITUDE OPERATION

Engine power is reduced the higher you operate above sea level. Output will be reduced approximately 3.5% for every 1000 feet of increased altitude from sea level.

High altitude adjustment is required for operation at altitudes over 5,000 ft. (1524 m). Operation without this adjustment will cause decreased performance, increased fuel consumption, and increased emissions.

NOTICE

DO NOT operate the generator at altitudes below 2,000 ft. (762 m) with the high altitude kit installed. Engine damage may occur

| High Altitude Carburetor Kit | Part# 518063 |

REMOTE START

WARNING

Verify that the area around the generator is clear before remote starting the generator.

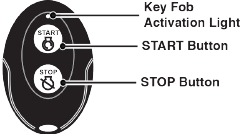

The remote start key fob included with the generator should be attached to the recoil handle or control panel. If your unit was shipped without a key fob, contact Westinghouse customer service.

The generator can be started remotely from up to 99 feet (30 meter) using the remote start key fob.

Note: As the batteries in the remote start key fob drain, operational distance will decrease.

PAIRING THE REMOTE START

Remote replacement batteries: (2) CR2016

If the remote start key fob is replaced or needs re-paired to the generator, follow this procedure.

Turn the generator battery switch to the ON position. The power indicator light will illuminate.

Push and hold the red Pairing button on the side of the control panel until the START/STOP button illuminates.

Push and hold the STOP button on the key fob until the START/STOP button illumination turns OFF. Release the button. The START/STOP button will illuminate after the button is released

- Push and hold the START button on the key fob until the START/STOP button illumination turns OFF. Release the button. The START/STOP button will illuminate after the button is released.

- Push the Pairing button on the side of the control panel until the START/STOP button illumination turns OFF. Release the button.

- Turn the generator battery switch to the OFF position. The remote is now paired.

BREAK-IN PERIOD

For proper break-in, DO NOT exceed 50% of the rated running watts (3750 watts) during the first five hours of operation.

Vary the load occasionally to allow stator windings to heat and cool and help seat the piston rings.

BEFORE STARTING THE GENERATOR

Verify that:

- The generator is placed in an safe, appropriate location.

- The generator is on a dry, flat, and level surface.

- The engine is filled with oil.

- All loads are disconnected.

Danger: Fire and explosion hazard. DO NOT move or tip the generator during operation.

STARTING THE ENGINE

- Verify that gasoline is in the fuel tank.

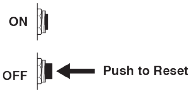

Turn the fuel tank valve to the ON position.

- Push the battery switch to the ON position.

- Choose the starting method:

- Remote Start: Push and hold the START button on the remote start key fob for one second.

- Push-Button Start: Push and hold the engine START/STOP button for two seconds.

Recoil Start: Manually close the choke if the engine is cold. Firmly grasp and pull the recoil handle slowly until you feel increased resistance, then pull rapidly.

Note: During Push-Button or Remote Start the engine will automatically set the choke and begin the start sequence. If the engine fails to start, the generator will attempt to start the engine two more times.

STOPPING THE ENGINE

- Turn off and unplug all connected electrical loads.

Important Information: NEVER start or stop the generator with electrical devices connected. - Let the generator run with no load for several minutes to stabilize internal temperatures of the engine.

- Push and hold the START/STOP button for one second or push STOP on the remote start key fob for one second.

Note: Alternately, if the generator is used infrequently, turn the fuel tank valve to the OFF position to limit the residual fuel remaining in the carburetor float bowl. The engine will stop when fuel in the carburetor and fuel line is exhausted. - Push the battery switch to the OFF position.

- If operating on LPG, turn the propane tank valve to the fully closed position.

FREQUENCY OF USE

If the generator will be used on an infrequent or intermittent basis (more than one month before next use), refer to the Battery Maintenance and Storage sections of this manual for information regarding battery charging and fuel deterioration.

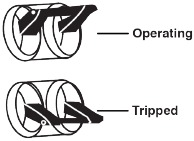

AC CIRCUIT BREAKERS

The circuit breakers will automatically switch OFF if there is a short circuit or a significant overload of the generator at each receptacle. The main circuit breaker will automatically switch OFF if the combined load of the receptacles exceeds 40 Amps.

If an AC circuit breaker switches OFF automatically, check that the appliance is working correctly and it does not exceed the rated load capacity of the circuit before resetting the AC circuit breaker ON.

Receptacle Circuit Breakers

Main Circuit Breaker

GENERATOR CAPACITY

NOTICE

DO NOT overload the generator's capacity. Exceeding the generator's wattage/amperage capacity can damage the generator and/or electrical devices connected to it.

Make sure the generator can supply enough continuous (running) and surge (starting) watts for the items you will power at the same time.

The total power requirements (Volts x Amps = Watts) of all appliances connected must be considered. Appliance and power tool manufacturers usually list rating information near the model or serial number.

To determine power requirements:

- Select the items you will power at the same time.

- Total the continuous (running) watts of these items. This is the amount of power the generator must produce to keep the items running. See the wattage reference chart below.

- Estimate how many surge (starting) watts you will need. Surge wattage is the short burst of power needed to start electric motor-driven tools or appliances such as a circular saw or refrigerator. Because not all motors start at the same time, total surge watts can be estimated by adding only the item(s) with the highest additional surge watts to the total rated watts from step 2.

Example:

| Tool or Appliance | Running Watts* | Starting Watts* |

| RV Air Conditioner (11,000 BTU) | 1010 | 1600 |

| TV (Tube Type) | 300 | 0 |

| RV Refrigerator | 180 | 600 |

| Radio | 200 | 0 |

| Light (75 Watts) | 300 | 0 |

| Coffee Maker | 600 | 0 |

| 2590 Total Running Watts* | 1600 Highest Starting Watts* | |

| Total Running Watts | 2590 | |

| Highest Starting Watts | + 1600 | |

| Total Starting Watts Needed | 4190 | |

*Wattages listed are approximate. Verify actual wattage.

POWER MANAGEMENT

To prolong the life of the generator and attached devices, use care when adding electrical loads to the generator. There should be nothing connected to the generator outlets before starting the engine. The correct and safe way to manage generator power is to sequentially add loads as follows:

- With nothing connected to the generator, start the engine as described in this manual.

- Plug in and turn on the first load, preferably the largest load you have.

- Permit the generator output to stabilize (the engine runs smoothly and the attached device operates properly).

- Plug in and turn on the next load.

- Again, permit the generator to stabilize.

- Repeat steps 4 and 5 for each additional load.

Wattage Reference

| Tool or Appliance | Estimated Running Watts* | Estimated Starting Watts* |

| Incandescent Lights (4 Quantity x 75 Watts) | 300 | 0 |

| TV (Tube Type) | 300 | 0 |

| Sump Pump (1/3 hp) | 800 | 1300 |

| Refrigerator or Freezer | 700 | 2200 |

| Well Pump (1/3 hp) | 1000 | 2000 |

| Furnace (1/2 hp) | 800 | 2350 |

| Radio | 200 | 0 |

| Drill (3/8", 4 amps) | 440 | 600 |

| Circular Saw (Heavy Duty, 7-1/4") | 1400 | 2300 |

| Miter Saw (10") | 1800 | 1800 |

| Table Saw (10") | 2000 | 2000 |

*Wattages listed are approximate. Verify actual wattage.

EXTENSION CORDS

WARNING

Asphyxiation hazard. Extension cords running directly into the home increase the risk of carbon monoxide poisoning through any openings. If an extension cord running directly into your home is used to power indoor items, there is a risk of carbon monoxide poisoning to people inside the home. ALWAYS use battery-powered carbon monoxide detector (s) that meet current UL 2034 safety standards when running the generator. Regularly check the detector (s) battery.

WARNING

Asphyxiation hazard. When operating the generator with extension cords, make sure the generator is located in an open, outdoor area, far away from occupied spaces with exhaust pointed away.

WARNING

Fire and electrocution hazard. NEVER use worn or damaged extension cords. Damaged or overloaded extension cords could overheat, arc, and burn resulting in death or serious injury.

Before connecting an AC appliance or power cord to the generator:

- Use grounded 3-prong extension cords, tools, and appliances, or double-insulated tools and appliances.

- Make sure the tool or appliance is in good working order. Faulty appliances or power cords can create a potential for electric shock.

- Make sure the electrical rating of the tool or appliance does not exceed the rated power of the generator or the receptacle being used.

EXTENSION CORD SIZING

Only use grounded 3-prong extension cords marked for outdoor use that are rated for the electrical load.

| ||

| Total Amperage | Minimum Gauge, Outdoor Rated | |

| Up to 50 FT (15M) | Up to 100 FT (30 M) | |

| Up to 10A | ||

| Up to 15A | ||

| Up to 20A |  | |

| Up to 30A |  | |

| Up to 35A |  |  |

ST SWITCH

The wGen7500 is compatible with the ST Switch, purchased separately. When utility power is on it will provide power (up to 120V @ 20A) to the appliances plugged into the 5-20R receptacle on the ST Switch. When utility power is lost the ST Switch automatically transfers input power from utility to generator power. When utility power is restored, the ST Switch transfers input power back to utility. Visit www.westinghouseoutdoorpower.com for more information.

TRANSPORTING

CAUTION

Weight hazard. ALWAYS have assistance when lifting the generator.

- Allow the generator to cool a minimum of 30 minutes before transporting.

- If operating on LPG, turn the propane tank valve to the fully closed position.

- Disconnect the LPG/propane hose from the generator and propane tank.

- Replace all protective covers on the generator control panel.

- Only use the generator's fixed frame to lift the unit or attach any load restraints such as ropes or tie-down straps. DO NOT attempt to lift or secure the generator by holding onto any of its other components.

- Keep the unit level during transport to minimize the possibility of fuel leakage or, if possible, drain the fuel or run the engine until the fuel tank is empty before transport.

- The generator wheels are only intended for hand transport. The wheels are not suitable for towing the generator either on or off-road.

- Use the extendable handle for one-person, hand transport. Only use the handle while the generator is OFF, stationary, and resting on a horizontal surface. DO NOT use the handle to lift the generator entirely off the ground, tow it, or up-end it.

CAUTION

Fire hazard. DO NOT up-end the generator or place it on its side. Fuel or oil can leak and damage to the generator may occur.

Setup Guide

To operate the Westinghouse WGen7500, follow these steps:

- Unpack and inspect the generator for any damage.

- Assemble the handle and wheel kit if it's not pre-assembled.

- Fill the oil reservoir with the recommended type and amount of oil.

- Add fuel to the tank, ensuring it is at least 1/4 full before starting.

- Connect any appliances or tools to the appropriate outlets.

- Use the remote start key fob or the electric start button to turn on the generator.

- Allow the generator to warm up before applying full load.

MAINTENANCE

WARNING

Accidental start-up. Disconnect the spark plug boot from the spark plug and disconnect the battery quick-connect plugs when performing maintenance on the generator.

MAINTENANCE SCHEDULE

Regular maintenance will improve performance and extend the service life of the generator. Follow the hourly or calendar intervals, whichever occurs first. More frequent service is required when operating in adverse conditions as noted below.

| Before Each Use | Check engine oil |

| After First 25 Hours or First Month | Change engine oil |

| After 50 Hours or Every 6 Months | Change engine oil 1 Clean air filter 2 |

| After 100 Hours or Every 6 Months | Inspect/clean spark arrestor Inspect/clean spark plug Replace fuel filter Inspect/adjust valve clearance3 |

| After 300 Hours or Every Year | Replace spark plug Replace air filter |

- Change oil every month when operating under heavy load or in high temperatures.

- Clean more often under dirty or dusty conditions. Replace air filter if it cannot be adequately cleaned.

- Recommend service to be performed by authorized Westinghouse service dealer.

MAINTENANCE REMINDERS

Maintenance reminder codes will be shown on the Data Display based on unit Lifetime Hours. The maintenance codes will be displayed until the unit is turned off. Refer to the Maintenance section for specific procedures.

| Maintenance Code | Required Maintenace |

| P25 | Change engine oil |

| P50 | Change engine oil, clean air filter |

| P100 | Change engine oil, clean air filter, replace fuel filter |

MAINTENANCE REPLACEMENT PARTS

| Description | Part Number |

| Air filter | 5046 |

| Oil drain plug crush washer | 94004 |

| Spark arrestor | 6866 |

| Battery, 9.0 AH | 511008 |

| Spark plug | 97108 |

AIR FILTER MAINTENANCE

WARNING

Fire hazard. NEVER use gasoline or other flammable solvents to clean the air filter. Use only household detergent soap to clean the air filter.

The air filter must be cleaned after every 50 hours of use or six months (frequency should be increased if the generator is operated in a dusty environment).

- Place the generator on a level surface and allow the engine to cool for several minutes.

Release the top and bottom clips then remove the air filter cover.

- Remove the air filters. Use compressed air to clean the coarse air filter.

Note: The foam air filter element is oil soaked. Use an appropriate cleaning container.

NOTICE

Avoid skin contact with engine oil. Wear protective clothing and equipment. Wash all exposed skin with soap and water. - Remove the foam air filter and wash it by submerging the element in a solution of household detergent soap and warm water. Slowly squeeze the foam to thoroughly clean.

NOTICE

DO NOT twist or tear the foam air filter element during cleaning or drying. Only apply slow but firm squeezing action. - Rinse the air filter element by submerging it in fresh water and applying a slow squeezing action. Allow the filter to dry thoroughly.

NOTICE

DO NOT pollute. Follow the guidelines of the EPA or other governmental agencies for proper disposal of hazardous materials. Consult local authorities or reclamation facility. - Dip the foam air filter in clean engine oil then squeeze out all excess oil. The engine will smoke when started if too much oil is left in the filter.

- Install the foam air filter in the housing, then the coarse air filter. Install the air cleaner cover and secure with the cover clips.

ENGINE OIL LEVEL CHECK

CAUTION

Avoid skin contact with engine oil. Wear protective clothing and equipment. Wash all exposed skin with soap and water.

NOTICE

ALWAYS use the specified engine oil. Failure to use the specified engine oil can cause accelerated wear and/or shorten the life of the engine.

When using the generator under extreme, dirty, dusty conditions or in extremely hot weather, change the oil more frequently.

Ambient air temperature will affect engine oil performance. Change the type of engine oil used based on weather conditions.

Check the engine oil level before each use or every 8 hours of operation.

- Place the generator on a level surface and allow the engine to cool for several minutes.

With a damp rag, clean around the oil dipstick then remove the dipstick.

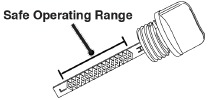

Wipe the dipstick clean, then insert it into the oil filler neck without screwing it in. Remove the dipstick and verify that the oil level is within safe operating range between the low (L) and high (H) marks on the dipstick.

- If low, add recommended engine oil incrementally and recheck until the level is between the L and H marks on the dipstick. DO NOT overfill. If over the full mark on the dipstick, drain the oil to reduce the oil level to the full mark.

- Replace the oil dipstick and hand-tighten.

ENGINE OIL CHANGE

When using the generator under extreme, dirty, dusty conditions or in extremely hot weather, change the oil more frequently. Change the oil while the engine is still warm from operation.

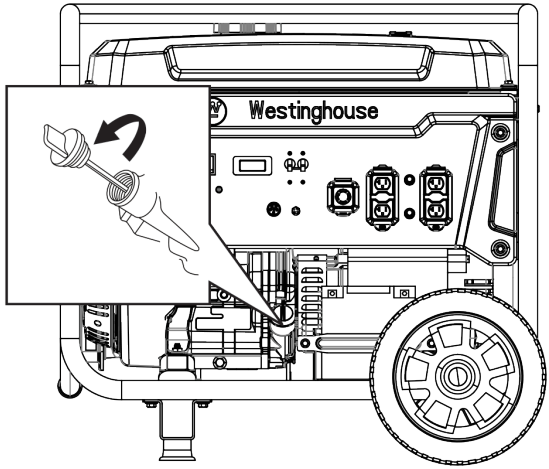

- Place the generator on a level surface and allow the engine to cool for several minutes.

- With a damp rag, clean around the oil dipstick. Remove the dipstick and wipe clean.

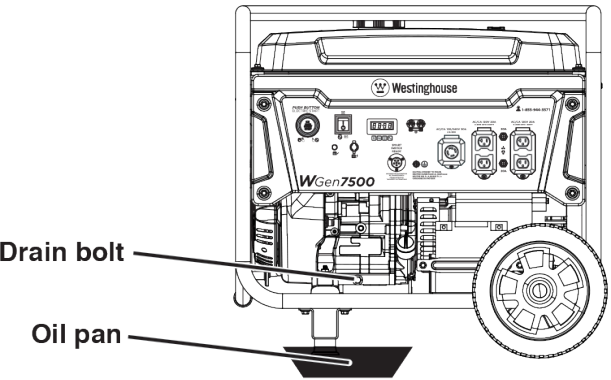

- Place an oil pan (or suitable container) under the oil drain bolt.

Using a 10mm wrench, remove the oil drain bolt and allow the oil the to drain.

- Install the oil drain bolt and tighten securely.

Note: A new oil drain plug crush washer is recommended at each oil change. - Slowly pour oil into the oil filler neck until oil the level is between the L and H marks on the dipstick. Stop frequently to check the oil level. DO NOT overfill.

Maximum oil capacity: 1.16 Quart (1.1 Liter) 7 Install the oil dipstick and hand-tighten. - Install the oil dipstick and hand-tighten.

NOTICE

DO NOT pollute. Follow the guidelines of the EPA or other governmental agencies for proper disposal of hazardous materials. Consult local authorities or reclamation facility.

SPARK PLUG MAINTENANCE

Inspect and clean the spark plug after every 100 hours of use or six months. Replace the spark plug after 300 hours of use or every year.

- Place the generator on a level surface and allow the engine to cool.

- Remove the spark plug boot by firmly pulling the spark boot directly away from the engine.

- Clean the area around the spark plug.

- Remove the spark plug with the included spark plug socket wrench.

NOTICE

NEVER apply any side load or move the spark plug laterally when removing the spark plug - Inspect the spark plug. Replace if electrodes are pitted, burned, or the insulator is cracked. Only use a recommended replacement plug.

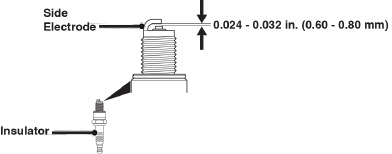

Measure the spark plug electrode gap with a wire-type feeler gauge. If necessary, correct the gap by carefully bending the side electrode.

Spark plug gap: 0.024 – 0.032 in. (0.60 – 0.80 mm)

- Carefully install the spark plug finger tight, then tighten as additional 3/8 to 1/2 turn with the spark plug wrench.

- Attach the spark plug boot.

SPARK ARRESTOR SERVICE

Allow the muffler to cool completely before servicing the spark arrestor. Check and clean the spark arrestor after every 100 hours of use or six months. Failure to clean the spark arrestor will result in degraded engine performance.

- Place the generator on a level surface.

Remove the cover screws and the muffler cover. Use a screw driver to remove the spark arrestor.

- Carefully remove the carbon deposits from the spark arrestor screen with a wire brush. The spark arrestor must be free of breaks and tears. Replace the spark arrestor if damaged.

- Reinstall the spark arrestor and muffler cover.

BATTERY MAINTENANCE

The battery shipped with the generator has been fully charged. A battery may lose some charge when not in use for prolonged periods of time.

Note: Once started, the generator will charge the battery after 30–60 minutes of use.

The included trickle charger can remain connected and will maintain the battery for an indefinite period of time. A red light on the charger indicates charging in progress. A green light indicates charging complete. Charge in a dry location.

- Plug the charger into the battery charging port on the control panel.

- Plug the wall receptacle end of the battery charger into a 120 Volt AC wall outlet.

BATTERY REPLACEMENT

WARNING

Burn hazard. The battery contains sulfuric acid (electrolyte) which is highly corrosive and poisonous. Wear protective clothing and eye protection when working near the battery. Keep children away from the battery.

CAUTION

Battery posts, terminals contain lead and lead compounds. Wash hands after handling.

- Loosen and remove the bolt on the battery hold-down plate and swing the plate out.

- Disconnect the quick-connect plugs and remove the battery from the unit.

- Disconnect the quick-disconnect cable leads from the battery.

- On the replacement battery, connect the white (-) quickconnect cable to the battery negative terminal. Slide the rubber boot over the connection hardware.

- Connect the red (+) quick-connect cable to the battery positive terminal. Slide the rubber boot over the connection hardware.

- Install the battery into the generator. Reinstall the battery hold-down plate and tighten the bolt.

- Connect the quick-connect plug.

NOTICE

Dispose of the used battery properly according to the guidelines established by your local or state government.

STORAGE

Proper storage preparation is required for trouble-free operation and generator longevity.

NOTICE

Gasoline stored for as little as 30 days can deteriorate, causing gum, varnish, and corrosive buildup in fuel lines, fuel passages, and the engine. This corrosive buildup restricts the flow of fuel, which can prevent the engine from starting after a prolonged storage period. The use of fuel stabilizer significantly increases the storage life of gasoline. Full-time use of fuel stabilizer is recommended.

Follow the manufacturer's instructions for use.

| STORAGE TIME | RECOMMENDED PROCEDURE |

| Less than 1 month | No service required. |

| 2 to 6 months | Fill with fresh gasoline and add gasoline stabilizer. Drain the carburetor float bowl. |

| 6 months or longer | Drain the fuel tank and carburetor float bowl. |

SHORT TERM STORAGE

- Allow the generator to cool a minimum of 30 minutes before storage.

- If operating on LPG, turn the propane tank valve to the fully closed position and disconnect the LPG/propane hose from the generator and propane tank.

- Replace all protective covers on the generator control panel.

- Wipe the generator with a moist cloth. Clean any debris from the muffler cooling vents.

- Store the generator in a well-ventilated, dry location away from sparks, open flames, pilot lights, heat, and other sources of ignition such as areas with a sparkproducing electric motor or where power tools are operated.

- DO NOT store the generator, gasoline, or propane tanks near furnaces, water heaters, or any other appliances that produce heat or have automatic ignitions.

- With the engine and exhaust system cool and all surfaces dry, cover the generator to keep out dust. DO NOT use a plastic sheet as a dust cover. Non-porous materials trap moisture and promote rust and corrosion.

LONG TERM STORAGE

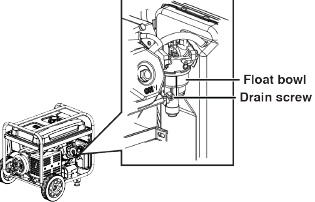

Even properly stabilized fuel can leave residue and cause corrosion if left long term. If storing the generator for two to six months, drain the float bowl to prevent gum and varnish buildup in the carburetor.

DRAINING THE FLOAT BOWL

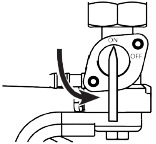

- Turn the fuel tank valve to the OFF position.

Locate the drain screw on the bottom of the carburetor float bowl.

- Place an appropriate gasoline container under the drain screw to catch the drained fuel.

- Loosen the float bowl drain screw and allow the fuel to drain. Tighten the float bowl drain screw.

DRAINING THE FUEL TANK

If storing the generator for longer than six months, drain the fuel tank to prevent fuel separation, deterioration, and deposits in the fuel system.

- Unscrew the fuel tank cap. Remove the fuel screen filter by slightly compressing it while removing it from the tank.

- Using a commercially available gasoline hand pump (not included), siphon the gasoline from the fuel tank into an approved gasoline container. DO NOT use an electric pump.

- Reinstall the fuel screen filter and the fuel tank cap.

- Start the generator and allow it to run until the generator engine stops.

- Push the battery switch to the OFF position.

- Disconnect the battery quick-connect plugs.

- Remove the spark plug.

- Put a teaspoon of engine oil into the cylinder and pull the recoil handle until resistance is felt. At this position the piston is coming up on its compression stroke and both valves are closed. Storing the engine in this position will help prevent internal corrosion. Return the recoil handle gently.

- Reinstall the spark plug. Leave the spark plug boot disconnected to prevent accidental starting.

VALVE CLEARANCE

NOTICE

Checking and adjusting valve clearance must be done when the engine is cold.

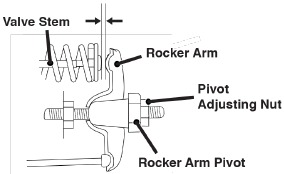

- Remove the rocker arm cover and carefully remove the gasket. If the gasket is torn or damaged, it must be replaced.

- Remove the spark plug so the engine can be rotated more easily.

- Rotate the engine to top dead center (TDC) by pulling the recoil handle slowly. Looking through the spark plug hole, the piston should be at the top (both valves are closed).

- Both the rocker arms should be loose at TDC on the compression stroke. If they are not, rotate the engine 360°.

Insert a feeler gauge between the rocker arm and the valve stem to measure valve clearance.

| Intake Valve | Exhaust Valve | |

| Valve Clearance | 0.0031 – 0.0047 in (0.08 – 0.12 mm) | 0.0051 – 0.0067 in (0.13 – 0.17 mm) |

| Torque | 8-12 N•m | 8-12 N•m |

- If an adjustment is necessary, hold the rocker arm pivot and loosen the pivot adjusting nut.

- Turn the rocker arm pivot to obtain the specified clearance. Hold the rocker arm pivot and re-tighten the pivot adjusting nut to the specified torque.

Torque: 106 inch-pound (12 N•m) - Perform this procedure for the other valve.

- Install the gasket, rocker arm cover, and spark plug.

TROUBLESHOOTING

| PROBLEM | POSSIBLE CAUSE | CORRECTION |

| Engine will not start | Battery switch in the OFF position. | Turn battery switch to the ON position. |

| Out of fuel. | Refuel. | |

| Bad fuel, generator stored without treating or draining gasoline, or refueled with bad gasoline. | Drain the fuel tank. Refuel with fresh gasoline. | |

| Dirty air filter. | Clean the air filter. | |

| Low engine oil level stopped generator. | If low oil LED illuminated, turn battery switch to the OFF position. Add engine oil. | |

| Spark plug wet with fuel (flooded engine). | Wait five minutes. Turn battery switch to the OFF position. Pull recoil handle rapidly several times. If the generator does not start, remove spark plug and dry. | |

| Spark plug faulty, fouled, or improperly gapped. | Gap or replace the spark plug. Reinstall. | |

| Fuel filter restricted, fuel system malfunction, fuel pump failure, ignition malfunction, valves stuck, etc. | Contact Westinghouse customer service tollfree at 1 (855) 944-3571. | |

| Battery drained. | Use the recoil handle to start the generator. | |

| Charge the battery. | ||

| Choke partially open or closed due to weak or disconnected battery. | Manually set the choke. See Maintenance section. | |

| Engine starts, then shuts down | Out of fuel. | Refuel. |

| Incorrect engine oil level. | Check engine oil level. | |

| Dirty air filter. | Clean the air filter. | |

| Contaminated fuel. | Drain the fuel tank. Refuel with fresh gasoline. | |

| Defective low oil level switch. | Contact Westinghouse customer service tollfree at 1 (855) 944-3571. | |

| Engine lacks power | Air filter restricted. | Clean or replace air filter. |

| Bad fuel, generator stored without treating or draining gasoline, or refueled with bad gasoline. | Drain the fuel tank. Refuel with fresh gasoline. | |

| Fuel filter restricted, fuel system malfunction, fuel pump failure, ignition malfunction, valves stuck, etc. | Contact Westinghouse customer service tollfree at 1 (855) 944-3571. | |

| Engine runs rough or bogs when load applied | Dirty air filter. | Clean the air filter. |

| Generator overloaded. | Unplug some devices. | |

| Faulty power tool or appliance. | Replace or repair tool or appliance. Stop and restart the engine. | |

| Fuel filter restricted, fuel system malfunction, fuel pump failure, ignition malfunction, valves stuck, etc. | Contact Westinghouse customer service tollfree at 1 (855) 944-3571. | |

| No power at AC receptacles | OUTPUT READY LED is OFF and OVERLOAD LED is ON. | Check AC load. Stop and restart engine. |

| Check the air inlet. Stop and restart the engine. | ||

| AC circuit breaker/s tripped. | Check AC loads and reset circuit breaker/s. | |

| Faulty power tool or appliance. | Replace or repair tool or appliance. Stop and restart the engine. | |

| Faulty generator. | Contact Westinghouse customer service tollfree at 1 (855) 944-3571. |

EXPLODED VIEWS AND PARTS LISTS

EXPLODED VIEW A

| NO. | PART# | DESCRIPTION |

| 1 | CRANKCASE ASSEMBLY | |

| 1.1 | 260218 | CRANKCASE |

| 1.2 | 93002 | AXLE BEARING |

| 1.3 | 93512 | CRANKCASE OIL SEAL |

| 1.4 | 93516 | GOVERNOR OIL SEAL |

| 1.5 | 263901 | GOVERNOR SHAFT |

| 1.6 | 96806 | SHAFT GASKET |

| 1.7 | 263902 | RETAINING CLIP |

| 1.8 | 265102 | OIL SENSOR ASSEMBLY |

| 1.9 | 91329 | BOLT M6X16 |

| 1.10 | 269901 | CABLE BLOCK |

| 1.11 | 245104 | LOW OIL SENSOR |

| 2 | 260319 | CRANKSHAFT |

| 3 | 260301 | BALANCE SHAFT |

| 4 | CRANKCASE COVER ASSEMBLY | |

| 4.1 | 93002 | AXLE BEARING |

| 4.2 | 93512 | CRANKCASE OIL SEAL |

| 4.3 | 240904 | CRANKCASE LOCATING PIN |

| 4.4 | 260111 | CRANKCASE COVER |

| 4.5 | 93015 | AXLE BEARING |

| 4.6 | 264301 | GOVERNOR GEAR ASSEMBLY |

| 4.7 | 96072 | CRANKCASE GASKET |

| 4.8 | 91349 | BOLT M8X40 |

| 4.9 | 265604- 295 | DIPSTICK |

| 5 | ALTERNATOR ASSEMBLY | |

| 5.1 | 266101 | VALVE LIFTER |

| 5.2 | 272003 | CAMSHAFT ASSEMBLY |

| 5.3 | 261901 | PUSH ROD |

| 6 | GOVERNOR ASSEMBLY | |

| 6.1 | 264001 | SPEED REGULATING ARM |

| 6.2 | 91325 | BOLT M6X12 |

| 6.3 | 264404 | SPEED CONTROLLER |

| 6.4 | 262701 | THROTTLE LEVER |

| 6.5 | 264201 | SPRING C |

| 6.6 | 264101 | SPRING B |

| 7 | PISTON & PISTON RING ASSEMBLY | |

| 7.1 | 261205 | PISTON |

| 7.2 | 261604 | PISTON RING ASSEMBLY |

| 7.3 | 261503 | CONNECTING ROD ASSEMBLY |

| 7.4 | 265501 | PISTON PIN |

| 7.5 | 261301 | PISTON PIN RING |

| 8 | 97108 | SPARK PULG |

| 9 | CYLINDER HEAD ASSEMBLY | |

| 9.1 | 271005 | CYLINDER HEAD |

| 9.2 | 271702 | INTAKE VALVE |

| 9.3 | 275902 | INTAKE VALVE |

| 9.4 | 261807 | EXHAUST VALVE |

| 9.5 | 93513 | VALVE SEAL |

| 9.6 | 266002 | VALVE SPRING |

| 9.7 | 260802 | VALVE LOCK CLAMP |

| 9.8 | 261805 | AIR INLET SPRING SEAT |

| 9.9 | 262201 | VALVE RETAINER ASSEMBLY |

| 9.10 | 262101 | ROCKER ARM |

| 9.11 | 261806 | TOP CAP |

| 9.12 | 91016 | AIR INLET STUD BOLT |

| 9.13 | 91007 | AIR EXHAUST STUD BOLT |

| 9.14 | 96083 | EXHAUST SEAL WASHER |

| 9.15 | 95207 | MUFFLER CONNECTING PIPE |

| 9.16 | 94206 | SPRING WASHER |

| 9.17 | 90011 | NUT M8 |

| 9.18 | 91818 | ROCKER ARM TIGHTENING ASSEMBLY |

| 9.19 | 260901 | CYLINDER HEAD LOCATING PIN |

| 9.20 | 96089 | CYLINDER HEAD GASKET |

| 9.21 | 91321 | BOLT M10X80 |

| 9.22 | 270501 | WIND-LEAD-COVER |

| 9.23 | 91325 | BOLT M6X12 |

| 9.24 | 96078 | INTAKE SEALING WASHER |

| 9.25 | 262301 | CARBURETOR CONNECTION BLOCK |

| 10 | CYLINDER HEAD COVER ASSEMBLY | |

| 10.1 | 261104 | CYLINDER HEAD COVER |

| 10.2 | 91819 | FASTENING BOLT |

| 10.3 | 95606 | BREATHER TUBE |

| 11 | CARBURETOR ASSEMBLY | |

| 11.1 | 262852 | CARBURETOR |

| 11.2 | 95713L | FUEL HOSE |

| 11.3 | 94403 | FUEL HOSE CLAMP |

| 11.4 | 94401 | FUEL HOSE SLEEVE |

| 11.5 | 260801 | CABLE CLIP |

| 11.6 | 249904 | STEPPER MOTOR |

| 11.7 | 92007 | CROSS SCREW STUD M4*8 |

| 11.8 | 249905 | STEPPER MOTOR DRIVE SHAFT |

| 11.9 | 244202 | SPRING |

| 11.10 | 269909 | BRACKET |

| 12 | AIR FILTER ASSEMBLY | |

| 12.1 | 90016 | NUT M6 |

| 12.2 | 262908-052 | AIR CLEANER ASSEMBLY |

| 13 | IGNITION COIL ASSEMBLY | |

| 13.1 | 97518 | IGNITION COIL |

| 13.2 | 91331 | BOLT M6X25 |

| 14 | FLYWHEEL ASSEMBLY | |

| 14.1 | 260407 | FLYWHEEL |

| 14.2 | 264601 | IMPELLER |

| 14.3 | 264501 | STARTER PULLEY |

| 14.4 | 90004 | FLYWHEEL NUT |

| 15 | RECOIL STARTER ASSEMBLY | |

| 15.1 | 91325 | BOLT M6X12 |

| 15.2 | 264738- 221B | STARTER ASSEMBLY |

| 15.3 | 5910-221 | RECOIL STARTER |

| 15.4 | 5943 | HANDLE |

| 16 | STARTER MOTOR ASSEMBLY | |

| 16.1 | 97415 | STARTING MOTOR |

| 16.2 | 91348 | BOLT M8*35 |

| 17 | 91817 | OIL DRAIN BOLT |

| 18 | 94004 | OIL DRAIN BOLT CRUSH WASHER |

| 19 | 96075 | HEADCOVER GASKET |

| 20 | 96081 | CARBURATOR GASKET |

| 21 | 5046 | AIR FILTER |

| 22 | 96086 | AIR FILTER GASKET |

EXPLODED VIEW B

| NO. | PART# | DESCRIPTION |

| 1 | FRAME ASSEMBLY | |

| 1.1 | 774010-116 | FRAME |

| 1.2 | 531314 | ISOLATOR |

| 1.3 | 90013 | NUT M10 |

| 1.4 | 90018 | NUT M8 |

| 1.5 | 90011 | NUT M8 |

| 1.6 | 91327 | BOLT M6X12 |

| 1.7 | 91343 | BOLT M8X16 |

| 1.8 | 544307 | GROUND WIRE |

| 1.9 | 94009 | TOOTH WASHER |

| 1.10 | 96120 | WASHER |

| 1.11 | 530606-116 | FUEL TANK BRACKET |

| 2 | CONTROL PANEL ASSEMBLY | |

| 2.1 | 91327 | BOLT M6X12 |

| 2.2 | 714305 | PANEL ASSEMBLY |

| 2.3 | 536002 | PUSH BUTTON SWITCH |

| 2.4 | 6393 | INDICATOR LIGHT |

| 2.5 | 6502 | ROCKER SWITCH |

| 2.6 | 6387 | 2.5MM CHARGING SOCKET |

| 2.7 | 6041 | DATA CENTER |

| 2.8 | 6488 | ST SWITCH |

| 2.9 | 6523 | BREAKER 30/2P/31A/1.25/CSA |

| 2.10 | 6386 | GROUND BOLT ASSEMBLY |

| 2.11 | 6385 | L14-30R RECEPTACLE 30A/125V/250V L14-30R/UL |

| 2.12 | 6848 | WATERPROOF CAP |

| 2.13 | 6275 | GFCI SOCKET |

| 2.14 | 6845 | WATERPROOF CAP |

| 2.15 | 6439-20 | THERMAL PROTECTOR 20A/CSA |

| 2.16 | 96120 | WASHER |

| 3 | FOOT BRACKET ASSEMBLY | |

| 3.1 | 91343 | BOLT M8X16 |

| 3.2 | 525608-116 | FOOT BRACKET ASSEMBLY |

| 3.3 | 531115 | FOOT BRACKET SHOCK ABSORBER |

| 3.4 | 91333 | BOLT M6X28 |

| 3.5 | 90023 | NUT M6 |

| 4 | ENGINE ASSEMBLY | |

| 4.1 | 540601 | AIR FILTER BRACKET |

| 4.2 | 1148420 120030 | ENGINE ASSEMBLY |

| 4.3 | 549603 | DUST BOARD |

| 4.4 | 91322 | BOLT M5X12 |

| 4.5 | 90016 | NUT M6 |

| 4.6 | 539602 | CRANKCASE COVER |

| 5 | CARBON CANISTER ASSEMBLY | |

| 5.1 | 95123 | CARBON CANISTER AND FUEL TANK CONNECTING PIPE |

| 5.2 | 91327 | BOLT M6X12 |

| 5.3 | 94423 | FUEL HOSE CLAMP |

| 5.4 | 94408 | FUEL HOSE CLAMP |

| 5.5 | 543601L | CARBON CANISTER |

| 5.6 | 95124 | CONNECTING PIPE |

| 5.7 | 94402 | FUEL HOSE CLAMP |

| 6 | HANDLE ASSEMBLY | |

| 6.1 | 527603 | HANDLE PLUG |

| 6.2 | 527612 | BOLT M10 |

| 6.3 | 526620-116 | HANDLE |

| 6.4 | 528607 | HANDLE COVER |

| 7 | WHEEL ASSEMBLY | |

| 7.1 | 94207 | FLAT WASHER |

| 7.2 | 523646 | WHEEL |

| 7.3 | 524619 | AXLE PIN |

| 7.4 | 548302 | COTTER PIN |

| 8 | FUEL TANK ASSEMBLY | |

| 8.1 | 700375L-116 | FUEL TANK ASSEMBLY |

| 8.2 | 6861 | FUEL GAUGE |

| 8.3 | 91460 | BOLT M6X25 |

| 8.4 | 518202 | FUEL SWITCH |

| 8.5 | 94403 | FUEL LINE CLAMP |

| 9 | MUFFLER ASSEMBLY | |

| 9.1 | 520305 | MUFFLER BRACKET |

| 9.2 | 91343 | BOLT M8X16 |

| 9.3 | 96002 | MUFFLER CONNECTING PIPE GASKET |

| 9.4 | 94206 | SPRING WASHER |

| 9.5 | 705944 | MUFFLER |

| 9.6 | 91347 | BOLT M8X30 |

| 10 | 60140041 | ALTERNATOR ASSEMBLY |

| 10.1 | 757551 | ALTERNATOR |

| 10.2 | 599019 | CARBON BRUSH |

| 10.3 | 6560 | TERMINAL ASSEMBLY |

| 10.4 | 532301 | BRACKET |

| 10.5 | 96813 | GASKET |

| 10.6 | 91717 | BOLT M10X1.25X275 |

| 10.7 | 91614 | BOLT M6X190 |

| 10.8 | 91322 | BOLT M5X12 |

| 10.9 | 534813 | AVR |

| 10.10 | 533302-221 | ALTERNATOR COVER |

| 10.11 | 91512 | BOLT M5X230 |

| 10.12 | 90009 | NUT M5 |

| 10.13 | 91323 | BOLT M5X16 |

| 10.14 | 544610 | GROUNDING WIRE |

| 10.15 | 532303-052 | BRACKET |

| 10.16 | 94204 | SPRING WASHER |

| 11 | BATTERY ASSEMBLY | |

| 11.1 | 91327 | BOLT M6X12 |

| 11.2 | 542614-116 | BATTERY HOLD DOWN |

| 11.3 | 512058 | BATTERY WIRING ASSEMBLY |

| 11.4 | 91325 | BOLT M6X12 |

| 12 | 519215 | FUEL TANK CAP |

| 13 | 6866 | SPARK ARRESTER |

| 14 | 518801 | FILTER |

| 15 | 511008 | BATTERY |

| 16 | 99504 | FUNNEL |

| 17 | 99010 | SPARK PLUG WRENCH |

| 18 | 99546 | OIL BOTTLE |

| 19 | 511076 | CHARGER |

| 20 | 99025 | WRENCH |

SCHEMATICS

Westinghouse WGen7500 Portable Generator Pros & Cons

Pros

- High Power Output: Capable of powering large appliances and tools.

- Durable Construction: Heavy-duty steel frame with lift brackets for easy handling.

- Convenient Features: Remote start key fob and electric start for easy operation.

- Comprehensive Outlets: Multiple outlets for versatile power distribution.

- Long Runtime: Up to 11 hours on a single fill at 25% load.

Cons

- Noisy Operation: Generates significant noise during operation.

- Weight and Size: Heavy and bulky, making it less portable than smaller generators.

- Higher Cost: More expensive compared to smaller or less powerful generators.

Customer Reviews

Customers praise the WGen7500 for its reliability and high power output. Many have used it successfully in various scenarios such as camping trips, home backup power during outages, and job site operations. Some users have noted that it is louder than expected but generally rate it highly for its performance and durability. Common complaints include the weight and size of the generator, which can make it difficult to transport without assistance.

Faqs

What is the maximum power output of the Westinghouse?

How long does the Portable run on a single fuel tank?

What types of outlets are available on the Generator?

What is the engine capacity of the Westinghouse?

Can I use the Westinghouse for sensitive electronics?

How do I start the Generator?

What maintenance tasks should I perform regularly on my Westinghouse WGen7500 Portable Generator?

Leave a Comment